Continuously innovating Animal Feed Additives

LASTEST NEWS

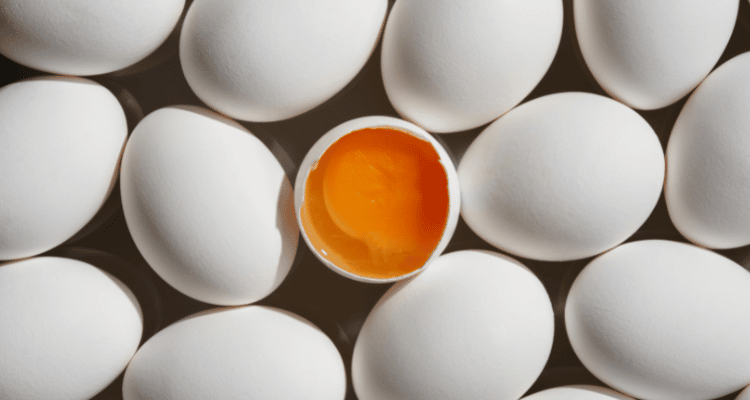

Enhance animal feed in a sustainable way

Use cases for poultry

feed additives ->

Use cases for pig

feed additives ->

Use cases for cattle

feed additives ->

Use cases for aqua

feed additives ->

Continuously innovating feed additives

Giving you a sustainable edge and animals what they need for optimal performance. Discover where we specialize and develop innovative solutions advancing animal nutrition.

NEW: On-farm solutions

Addressing key challenges on livestock farms and offering greater flexibility and precision in application at crucial times of animal production cycles.

Keep learning more about animal feed additives to stay ahead

PANCOSMA BLOG

Keep learning about topics on advancing animal nutrition and stay in the loop of who and what is moving and shaking the Pancosma world.

Pancosma Today

News

Pancosma controls and maintains this web site from the EU and makes no representation that the information provided on or via this website is appropriate or available for use in other locations. If you use this website from other locations, you are responsible for compliance with applicable local laws, regulations and terms of use depending on the country. Information and statements contained in this website have not been evaluated by the US Food and Drug Administration and Canadian Food Inspection Agency. The products are not intended to diagnose, cure or prevent any diseases.